The IP Code, or Ingress Protection Code, IEC standard 60529, sometimes interpreted as International Protection Code, classifies and rates the degree of protection provided by mechanical casings and electrical enclosures against intrusion, dust, accidental contact, and water. It is published by the International Electrotechnical Commission (IEC). The equivalent European standard is EN 60529.

Overview

The standard aims to provide users more detailed information than vague marketing terms such as waterproof. For example, a cellular phone rated at IP68 is "dust resistant" and can be "immersed in 1.5 meters of freshwater for up to 30 minutes". Similarly, an electrical socket rated IP22 is protected against insertion of fingers and will not be damaged or become unsafe during a specified test in which it is exposed to vertically or nearly vertically dripping water. IP22 or IP2X are typical minimum requirements for the design of electrical accessories for indoor use.

The digits indicate conformity with the conditions summarized in the tables below. The digit 0 is used where no protection is provided. The digit is replaced with the letter X when insufficient data has been gathered to assign a protection level.

There are no hyphens in a standard IP code. IPX-8 (for example) is thus an invalid IP code.

This article summarizes a combination of IEC 60529 (also EN 60529) and other standards, such as ISO 20653. The original documents are available for purchase, and have important and specific requirements that cannot be fully reprinted due to copyright restrictions. This often includes drawings specifying the required test equipment, such as the shape of water nozzles used for water jet testing. Additional standards are often referenced that may contain important information. One must refer to the latest revision of the required standard when conducting formal tests for agency certification.

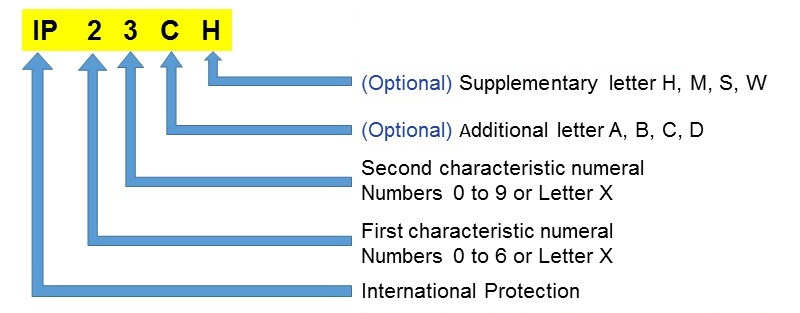

Code breakdown

This table shows what each digit or part of the IP code represents.

| Code letters | First characteristic numeral: Solid particle protection | Second digit: Liquid ingress protection | Third digit: Mechanical impact resistance | Additional letter: Other protections | Supplementary letter: Other protections |

|---|---|---|---|---|---|

| IP (Ingress Protection) | Single numeral: 0–6 or letter X | Single numeral: 0–8 or letter X | Single numeral: 0–9 | Single letter | Single letter |

| Mandatory | Mandatory | Mandatory | No longer used | Optional | Optional |

First digit: Solid particle protection

The first digit indicates the level of protection that the enclosure provides against access to hazardous parts (e.g., electrical conductors, moving parts) and the ingress of solid foreign objects.

| Level sized | Effective against | Description |

|---|---|---|

| X | — | X means there is no data available to specify a protection rating with regard to this criterion. |

| 0 | — | No protection against contact and ingress of objects |

| 1 | >50 mm2.0 in | Any large surface of the body, such as the back of a hand, but no protection against deliberate contact with a body part |

| 2 | >12.5 mm 0.49 in |

Fingers or similar objects |

| 3 | >2.5 mm 0.098 in |

Tools, thick wires, etc. |

| 4 | >1 mm 0.039 in |

Most wires, slender screws, large ants etc. |

| 5 | Dust protected | Ingress of dust is not entirely prevented, but it must not enter in sufficient quantity to interfere with the satisfactory operation of the equipment. |

| 6 | Dust-tight | No ingress of dust; complete protection against contact (dust-tight). A vacuum must be applied. Test duration of up to 8 hours based on airflow. |

Second digit: Liquid ingress protection

The second digit indicates the level of protection that the enclosure provides against harmful ingress of water. The ratings for water ingress are not cumulative beyond IPX6. A device that is compliant with IPX7 (covering immersion in water) is not necessarily compliant with IPX5 or IPX6 (covering exposure to water jets). A device that meets both tests is indicated by listing both tests separated by a slash, e.g. IPX5/IPX7.

| Level | Protection against | Effective against | Details |

|---|---|---|---|

| X | — | — | X means there is no data available to specify a protection rating with regard to these criteria. |

| 0 | None | — | No protection against ingress of water |

| 1 | Dripping water | Dripping water (vertically falling drops) shall have no harmful effect on the specimen when mounted in an upright position onto a turntable and rotated at 1 RPM. | Test duration: 10 minutes

Water equivalent to 1 mm (0.039 in) rainfall per minute |

| 2 | Dripping water when tilted at 15° | Vertically dripping water shall have no harmful effect when the enclosure is tilted at an angle of 15° from its normal position. A total of four positions are tested within two axes. | Test duration: 2.5 minutes for every direction of tilt (10 minutes total) Water equivalent to 3 mm (0.12 in) rainfall per minute |

| 3 | Spraying water | Water falling as a spray at any angle up to 60° from the vertical shall have no harmful effect, utilizing either: a) an oscillating fixture, or b) A spray nozzle with a counterbalanced shield.

Test a) is conducted for 5 minutes, then repeated with the specimen rotated horizontally by 90° for the second 5-minute test. Test b) is conducted (with shield in place) for 5 minutes minimum. |

For a spray nozzle:

Test duration: 1 minute per square meter for at least 5 minutes Water volume: 10 liters per minute (0.037 impgal/s) Pressure: 50–150 kPa (7.3–21.8 psi) For an oscillating tube: Test duration: 10 minutes Water volume: 0.07 liters per minute (0.00026 impgal/s) per hole |

| 4 | Splashing of water | Water splashing against the enclosure from any direction shall have no harmful effect, utilizing either:

a) an oscillating fixture, or b) A spray nozzle with no shield. Test a) is conducted for 10 minutes. b) is conducted (without shield) for 5 minutes minimum. |

Oscillating tube: Test duration: 10 minutes, or spray nozzle (same as IPX3 spray nozzle with the shield removed) |

| 5 | Water jets | Water projected by a nozzle (6.3 mm (0.25 in)) against enclosure from any direction shall have no harmful effects. | Test duration: 1 minute per square meter for at least 3 minutes

Water volume: 12.5 litres per minute Pressure: 30 kPa (4.4 psi) at distance of 3 meters (9.8 ft) |

| 6 | Powerful water jets | Water projected in powerful jets (12.5 mm (0.49 in)) against the enclosure from any direction shall have no harmful effects. | Test duration: 1 minute per square meter for at least 3 minutes

Water volume: 100 liters per minute (0.37 impgal/s) Pressure: 100 kPa (15 psi) at distance of 3 meters (9.8 ft) |

| 6K | Powerful water jets with increased pressure | Water projected in powerful jets (6.3 mm (0.25 in) nozzle) against the enclosure from any direction, under elevated pressure, shall have no harmful effects. Found in DIN 40050, and not IEC 60529. | Test duration: at least 3 minutes[citation needed] Water volume: 75 liters per minute (0.27 impgal/s) Pressure: 1,000 kPa (150 psi) at distance of 3 meters (9.8 ft) |

| 7 | Immersion, up to 1 meter (3 ft 3 in) depth | Ingress of water in harmful quantity shall not be possible when the enclosure is immersed in water under defined conditions of pressure and time (up to 1 meter (3 ft 3 in) of submersion). | Test duration: 30 minutes.

Tested with the lowest point of the enclosure 1,000 mm (39 in) below the surface of the water, or the highest point 150 mm (5.9 in) below the surface, whichever is deeper. |

| 8 | Immersion, 1 meter (3 ft 3 in) or more depth | The equipment is suitable for continuous immersion in water under conditions which shall be specified by the manufacturer. However, with certain types of equipment, it can mean that water can enter but only in such a manner that it produces no harmful effects. The test depth and duration is expected to be greater than the requirements for IPx7, and other environmental effects may be added, such as temperature cycling before immersion. | Test duration: agreement with manufacturer

Depth specified by the manufacturer, generally up to 3 meters (9.8 ft) |

| 9K | Powerful high-temperature water jets | Protected against close-range high pressure, high-temperature spray downs.

Smaller specimens rotate slowly on a turntable, from 4 specific angles. Larger specimens are mounted in the intended position when being used, no turntable required, and are tested freehand for at least 3 minutes at a distance of 0.15–0.2 meters (5.9 in–7.9 in). The specific requirements for the test nozzle are shown in figures 7, 8, & 9 of IEC (or EN) 60529. This test is identified as IPx9 in IEC 60529. |

Test duration: Fixture: 30 sec. in each of 4 angles (2 min. total), Freehand: 1 min/m2, 3 min. minimum

Water volume: 14–16 liters per minute (0.051–0.059 impgal/s) Pressure: 8–10 MPa (80–100 bar) at distance of 0.10–0.15 meters (3.9 in–5.9 in) Water temperature: 80 °C (176 °F) |

(All tests with the letter "K" are defined by ISO 20653 (replacing DIN 40050-9) and are not found in IEC 60529, except for IPx9 which is the same as the IP69K water test.)

Additional letter (optional)

For the protection of personnel against access to hazardous parts with:

| Letter | Meaning |

|---|---|

| A | Back of hand |

| B | Finger |

| C | Tool |

| D | Wire |

Supplementary letter (optional)

For the protection of equipment specific to:

| Letter | Meaning |

|---|---|

| H | High voltage apparatus |

| M | Motion during water test |

| S | Stationary during water test |

| W | Weather conditions |

The letter K is specified in DIN 40050-9, and not in IEC 60529.

IP69K and IPx9

DIN 40050-9 extended the newer IEC 60529 rating system with an IP69K rating for high-pressure, high-temperature wash-down applications. Enclosures conforming with ISO 20653:2013 must not only be dust-tight (IP6X), but also able to withstand high-pressure and steam cleaning.

The IP69K standard was originally developed for road vehicles—especially those that need regular intensive cleaning (dump trucks, concrete mixers, etc.)—but it also finds use in other areas, such as food processing machinery and car wash systems. It was superseded by ISO 20653:2013 Road Vehicles-Degrees of protection (IP code), and complemented by the addition of a level 9 water ingress testing to IEC 60529, which includes essentially the same spray test as IP69K, but also includes, in Figure 10 of the standard, a drawing for a test fixture designed to verify the correct water pressure.

Test setup

The test specifies a spray nozzle that is fed with 80 °C water at 8–10 (80–100 bar) and a flow rate of 14–16 L/min. The nozzle is held 10–15 cm from the tested device at angles of 0°, 30°, 60° and 90° for 30 seconds each. The test device sits on a turntable that completes a rotation once every 12 seconds (5 rpm). The IPx9 specification details a freehand method for testing larger specimens that will not fit on a turntable (see table above). The free hand method also requires (at least) one additional minute of spray time (1 min/m2, 3 min. minimum). The test distance also increases to .175 m (0.15–0.2 m per section 14.2.9).

North America (NEMA rating)

In the US, the National Electrical Manufacturers Association defines NEMA enclosure types in NEMA standard number 250. The following table outlines which IEC 60529 IP code each respective NEMA rating meets. Ratings between the two standards are not directly equivalent: NEMA ratings also require additional product features and tests (such as functionality under icing conditions, enclosures for hazardous areas, knock-outs for cable connections and others) not addressed by IP ratings.

| NEMA enclosure[9] | IP Code |

|---|---|

| 1 | IP20 |

| 2 | IP22 |

| 3, 3X, 3S, 3SX | IP55 |

| 3R, 3RX | IP24 |

| 4, 4X | IP66IP65 |

| 5 | IP53 |

| 6 | IP67 |

| 6P | IP68 |

| 12, 12K, 13 | IP54 |

(Wikipedia Septemper 2020)